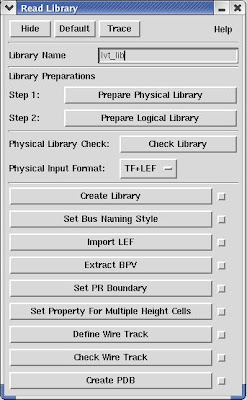

There are two reference libraries required. One is low Vt cell library and another is high Vt cell library. These libraries have two different height cells. Reference libraries are created as per the standard synopsys flow. Library creation flow is given in Figure 1. Read_lib command is used for this purpose. As TF and LEF files are available TF+LEF option is chosen for library creation. After the completion of the physical library preparation steps, logical libraries are prepared.

Different Unit Tile Creation

The unit tile height of lvt cells is 2.52 µ and hvt cells are 1.96 µ. Hence two separate unit tiles have to be created and should be added in the technology file. Hvt reference library is created with the unit tile name “unit” and lvt reference library is created with unit tile name “lvt_unit”. By default “unit” tile is defined in technology file and the other unit tile “lvt_unit” is also added to the technology file.

Figure 2. Tile height specifications in library preparation

Floor Planning

70% of the core utilization is provided. Aspect ratio is kept at 1. Rows are flipped, double backed and made channel less. No Top Design Format (TDF) file is selected as default placement of the IO pins are considered. Since we have multi height cells in the reference library separate placement rows have to be provided for two different unit tiles. The core area is divided into two separate unit tile section providing larger area for Hvt unit tile as shown in the Figure 3.

Figure 3. Different unit tile placement

First as per the default floor planning flow rows are constructed with unit tile. Later rows are deleted from the part of the core area and new rows are inserted with the tile “lvt_unit”. Improper allotment of area can give rise to congestion. Some iteration of trial and error experiments were conducted to find best suitable area for two different unit tiles. The “unit” tile covers 44.36% of core area while “lvt_unit” 65.53% of the core area. PR summary report of the design after the floor planning stage is provided below.

PR Summary:

Number of Module Cells: 70449

Number of Pins: 368936

Number of IO Pins: 298

Number of Nets: 70858

Average Pins Per Net (Signal): 3.20281

Chip Utilization:

Total Standard Cell Area: 559367.77

Core Size: width 949.76, height 947.80; area 900182.53

Chip Size: width 999.76, height 998.64; area 998400.33

Cell/Core Ratio: 62.1394%

Cell/Chip Ratio: 56.0264%

Number of Cell Rows: 392

Placement Issues with Different Tile Rows

Legal placement of the standard cells is automatically taken care by Astro tool as two separate placement area is defined for multi heighten cells. Corresponding tile utilization summary is provided below.

PR Summary:

[Tile Utilization]

============================================================

unit 257792 114353 44.36%

lvt_unit 1071872 702425 65.53%

============================================================

But this method of placement generates unacceptable congestion around the junction area of two separate unit tile sections. The congestion map is shown in Figure 4.

Figure 4. Congestion

There are two congestion maps. One is related to the floor planning with aspect ratio 1 and core utilization of 70%. This shows horizontal congestion over the limited value of one all over the core area meaning that design can’t be routed at all. Hence core area has to be increased by specifying height and width. The other congestion map is generated with the floor plan wherein core area is set to 950 µm. Here we can observe although congestion has reduced over the core area it is still a concern over the area wherein two different unit tiles merge as marked by the circle. But design can be routable and can be carried to next stages of place and route flow provided timing is met in subsequent implementation steps.

Tighter timing constraints and more interrelated connections of standard cells around the junction area of different unit tiles have lead to more congestion. It is observed that increasing the area isn't a solution to congestion. In addition to congestion, situation verses with the timing optimization effort by the tool. Timing target is not able to meet. Optimization process inserts several buffers around the junction area and some of them are placed illegally due to the lack of placement area.

Corresponding timing summary is provided below:

Timing/Optimization Information:

[TIMING]

Setup Hold Num Num

Type Slack Num Total Target Slack Num Trans MaxCap Time

========================================================

A.PRE -3.491 3293 -3353.9 0.100 10000.000 0 8461 426 00:02:26

A.IPO -0.487 928 -271.5 0.100 10000.000 0 1301 29 00:01:02

A.IPO -0.454 1383 -312.8 0.100 10000.000 0 1765 36 00:01:57

A.PPO -1.405 1607 -590.9 0.100 10000.000 0 2325 32 00:00:58

A.SETUP -1.405 1517 -466.4 0.100 -0.168 6550 2221 31 00:04:10

========================================================

Since the timing is not possible to meet design has to be abandoned from subsequent steps. Hence in a multi vt design flow cell library with multi heights are not preferred.

References

[1] Astro, User Guide, Version X-2005.09, September 2005